Posted: Thursday, 6 November 2025

We believe that by targeting the microbial and chemical compounds

responsible for unpleasant smells, UV technology can significantly improve

indoor air quality across a wide range of environments.

What Causes Odours in Air Systems?

Airborne odours can come from a range of sources:

-

Microbial activity: Bacteria, mould, and

fungi release odorous gases as by-products of growth, especially in humid

or organic-rich environments.

- Volatile Organic

Compounds (VOCs):

Emitted by solvents, packaging, equipment, or cleaning agents.

- Airborne contaminants: Dust, smoke, waste

vapour, or process emissions that carry a distinct odour.

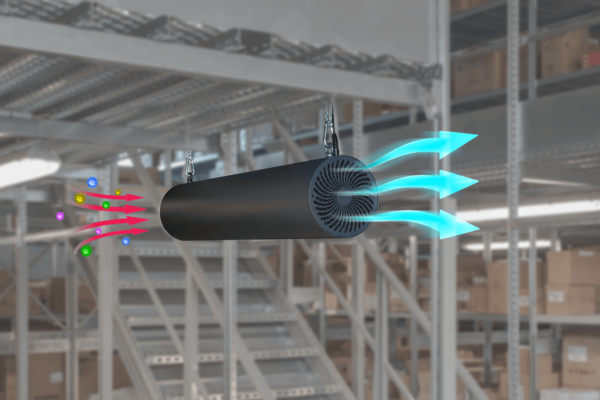

How UV Air Systems Help Reduce Odours

UV systems address odours already present in the air using three primary

mechanisms:

1. Microbial inactivation

UV-C light (254 nm) neutralises airborne bacteria, fungi and viruses,

reducing the biological sources of unpleasant smells.

2. Photocatalytic Oxidation

(PCO)

When combined with catalysts like titanium dioxide, UV light triggers

chemical reactions that break down VOCs and odour compounds into odourless

water vapour and carbon dioxide.

3. Combined UV + Filtration

UV systems used alongside activated carbon or advanced filters remove and

neutralise lingering smells while preventing microbial growth on the

filters themselves.

Where UV Air Systems Add Value

- UV systems are particularly useful in areas where odours are introduced by

environmental conditions:

- Food & Beverage: Odours from

ingredients, cooking, or cleaning processes can remain in the air.

- Aquaculture: Air near tanks or wet

areas can carry strong biological smells.

- Laboratories &

Healthcare:

Chemical vapours and biological materials contribute to airborne odours.

- Commercial HVAC: Odours from occupant

activity or external pollution can circulate through indoor environments.

- Industrial Facilities: Manufacturing and

processing operations often generate persistent VOCs.

System Design Considerations

To tackle environmental odour effectively, UV systems should be designed with

the following in mind:

- Airflow & exposure

time:

Air must pass long enough through the UV or PCO zone for treatment to

occur.

- Target-specific

configuration:

UV dose and catalyst combinations should match the types of odours present

(biological vs chemical).

- Media integration: Combining UV with

activated carbon or other filters improves efficiency.

- Safety & compliance: UV systems must avoid

ozone production and be shielded to protect occupants.

- Maintenance: Regular lamp

replacement and system checks ensure ongoing performance.

Why Alpha-Purify?

Alpha-Purify supplies premium UV lamps and components to OEMs and system

designers worldwide. With ISO 9001-certified production in the UK, we provide:

Our UV technology is trusted in air treatment units across

aquaculture, food production, labs and commercial buildings, helping reduce

airborne odours and improve overall air quality.

If you’re battling persistent odours in indoor air, the issue may lie in the

environment. A UV air system can help neutralise those smells, prevent

microbial build-up, and keep air fresher for longer.

Contact Us to discuss your challenge.