Posted: Wednesday, 14 May 2025

What is TOC and Why is it a Problem?

Total Organic Carbon (TOC) refers to the amount of carbon found in organic compounds present in water. It’s not a single contaminant but a general indicator of water quality. TOCs come from various natural and synthetic sources such as decomposed plant material, industrial waste, pesticides, solvents, and more.

While TOCs themselves aren’t always toxic, they act as a precursor to many potential problems in water systems:

- Bacterial growth - TOCs provide a food source for microbes, increasing biofouling risks.

- By-product formation - During chlorination, TOCs can react to form harmful disinfection by-products (DBPs) like trihalomethanes.

- Equipment damage - TOC build-up can foul membranes and degrade sensitive components in high-purity water systems.

TOC control is especially critical in ultra-pure water (UPW) applications such as semiconductor manufacturing, pharmaceuticals, and power generation. In these industries, TOC levels often need to be under 1 part per billion (ppb), making effective treatment essential and extremely challenging.

Why TOCs are Difficult to Remove

TOCs can exist in both dissolved and particulate forms, and they’re chemically diverse ranging from simple alcohols to complex hydrocarbons. This variability makes them difficult to treat using traditional filtration or chemical methods.

Membrane filtration (like RO) removes some TOCs, but not all, and chemical oxidation methods (like ozone) can be complex and costly to manage. What’s needed is a reliable, non-chemical method that breaks down organics without introducing new contaminants or requiring intensive handling.

UV Technology: A Different Approach for TOC Reduction

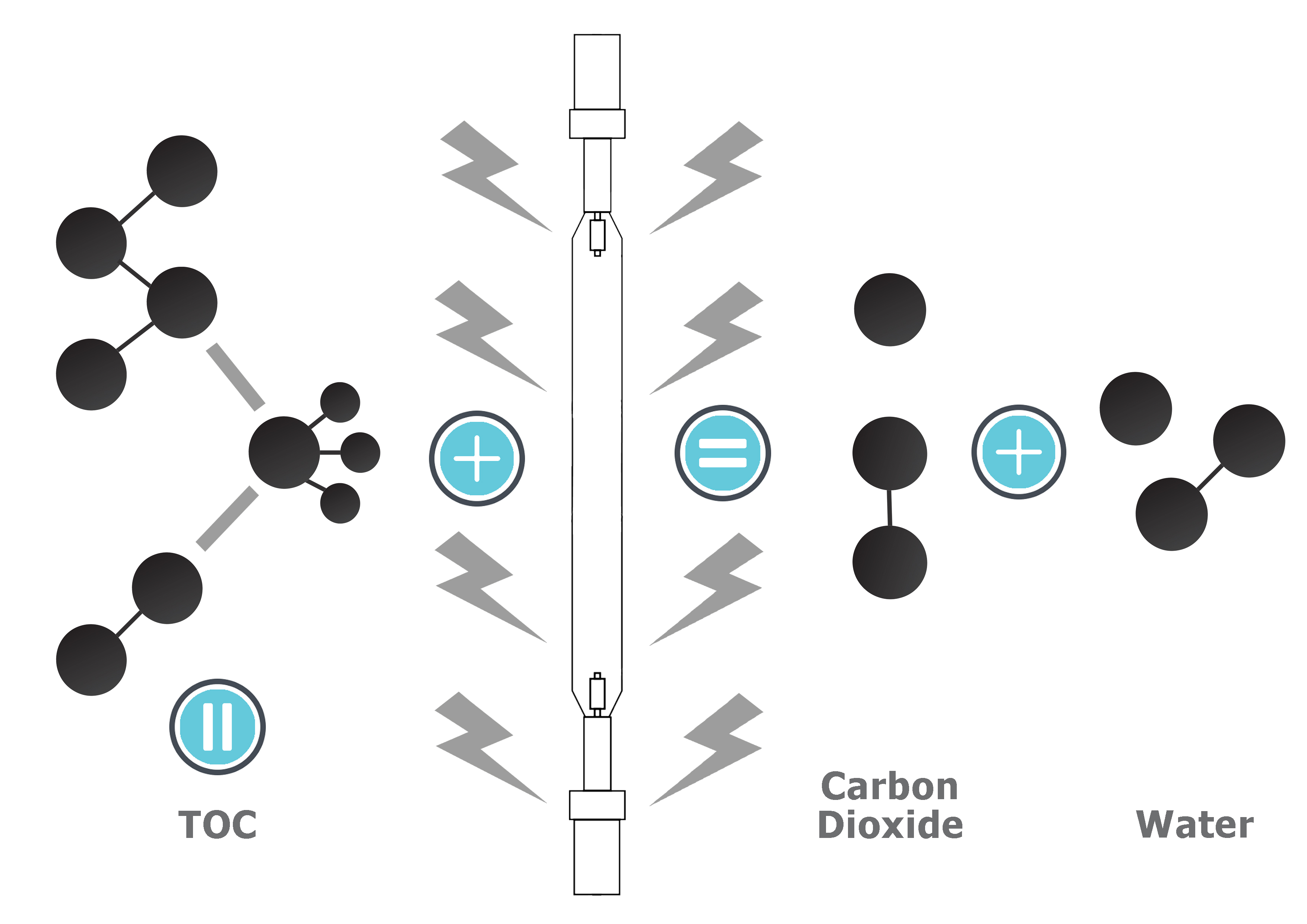

Ultraviolet (UV) light, specifically shortwave UVC radiation is increasingly being used to reduce TOC levels via a process called UV oxidation. In this process, UV lamps are used to break down organic molecules into carbon dioxide and water.

In ultra-pure water systems, UV is often installed before ion exchange or reverse osmosis to pre-treat water and reduce the TOC load, extending the lifespan of those more sensitive processes.

UV systems are compact, easy to integrate, and operate with minimal maintenance which are considerations in environments like cleanrooms or onboard marine vessels.

Why Medium-Pressure UV Lamps Are Particularly Effective

Alpha-Purify’s range of medium-pressure UV lamps is particularly suited to TOC reduction because they emit a broad spectrum of UV wavelengths. This ensures more comprehensive photolysis of organic contaminants compared to low-pressure lamps, which emit at a single wavelength (254 nm).

Medium-pressure lamps are especially effective in high-flow systems or where water has varying organic load, such as in industrial or marine applications. They’re also ideal for integration into OEM-designed purification systems where robust and high-output UV is required.

UV for TOC Reduction: Applications Across Industries

UV oxidation is now standard in several high-stakes industries:

- Pharmaceutical and biotechnology - For ensuring ultrapure water used in injections or lab analysis.

- Semiconductor manufacturing - Where trace levels of TOCs can affect chip production yields.

- Food and beverage - For rinse water and ingredient preparation, ensuring compliance with safety standards.

- Marine and offshore - As part of ballast water and potable water purification systems.

Conclusion: UV Is a Proven, Scalable Solution to TOC Challenges

Controlling TOC is critical for maintaining water purity, system efficiency, and product safety across a wide range of industries. Ultraviolet oxidation, particularly using medium-pressure UV lamps offers a proven, low-maintenance, and chemical-free way to meet strict TOC limits.

Our expert team can help you specify the right solution for your TOC control needs, whether for a new system or an upgrade. Contact Us today.