Posted: Monday, 23 June 2025

Why Quartz Sleeves Matter in UV Disinfection

In UV based disinfection systems, quartz sleeves serve two key purposes:

-

They protect the UV lamp from water, air, or surface contaminants.

-

They maintain optimal UV-C transmission, allowing the germicidal light to pass through efficiently while keeping the lamp dry and stable.

Over time, sleeves can become fouled with mineral build-up, biofilm, or scratches, especially in hard water or high-load environments. When this happens, UV transmission can drop, reducing disinfection effectiveness. That's why regular inspection and replacement are essential for system reliability.

When Should You Replace a Quartz Sleeve?

- During routine UV lamp replacement (recommended annually or based on operational hours)

-

If there is visible fouling, scaling, or discolouration

If there are cracks, chips or scratches

-

When UV system output readings drop unexpectedly (indicated by sensors)

The Three Types of Quartz Sleeves from Alpha-Purify

Alpha-Purify offers a full range of precision-made quartz sleeves, manufactured to tight tolerances and suitable for a wide variety of UV disinfection systems. We only use high-purity, optical-grade quartz that ensures excellent UV-C transmittance.

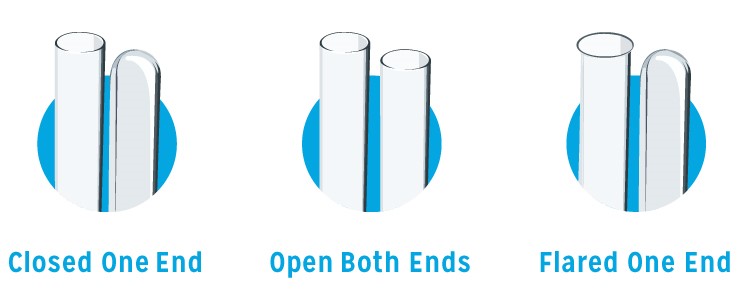

Here are the three common configurations we supply:

Open Both Ends Application:

Common in water disinfection systems with O-ring seals on both ends.

Advantage: Simple to install and remove.

Compatible with: Many standard low- and medium-pressure UV systems.

Closed One End Application:

Used when the UV lamp is inserted into the sleeve from one side only.

Advantage: Prevents contamination from entering one side of the system.

Common in: High-pressure or compact UV units.

Flared One End

Application:

Offers a more secure seal with specific fittings or clamp assemblies.

Advantage: Reduces leakage risk in high-pressure or industrial applications.

Ideal for: OEMs and custom UV system designs.

Need help identifying your sleeve type? Our technical team is ready to assist with exact replacements or custom builds. Contact Us today.

Step-by-Step Quartz Sleeve Replacement

Always turn off and isolate the UV system before starting maintenance.

1. Turn Off the UV System

Ensure the UV lamp is off and the system is powered down according to the system manufacturers instructions.

2. Access the Sleeve

2. Access the Sleeve

Remove the housing where the sleeve is mounted. Handle all components with clean gloves.

3. Remove the Old Sleeve

Slide out the old sleeve carefully. Never force or twist harshly.

4. Clean or Replace O-Rings

Inspect and, if necessary, replace the O-rings. A damaged seal can lead to leaks or sleeve breakage.

5. Insert the New Sleeve

Carefully insert the new quartz sleeve, ensuring the correct orientation (especially for closed or flared ends).

6. Seal and Test

Secure the sleeve. Power the system back on and test for leaks and proper lamp function.

Why Choose Alpha-Purify Quartz Sleeves?

✅ High-purity quartz for superior UV transmission

✅ Manufactured to exact specifications

✅ Compatibility with global brands and OEM systems

✅ Fast global shipping and technical support

Whether you're sourcing a replacement sleeve or designing a new system, Alpha-Purify can supply sleeves to your exact specifications including custom lengths, diameters, and end fittings.

Talk to the Experts

Need help choosing the right quartz sleeve or managing a complete system overhaul? Our specialists work with water treatment professionals, OEM engineers, and maintenance teams worldwide to keep UV disinfection systems performing at their best.

Contact Us today for expert advice or a quote on quartz sleeve replacements.